What Are

Z Numbers?

See list of vehicles that OEM specified with Mechanical Attachment

The Friction Materials Standards Institute (FMSI®) has just updated its industry-standard part numbering system to include a total of 102 Z-Numbers.

These numbers indicate brake pads specified by OEMs to use mechanical retention, denoted by a 'Z' designation.

Mechanically Attached Brakes

Right out of the box, Galvanized NRS Brakes have a technology you can see. Rust resistant, unpainted Galvanized Steel that incorporates an award winning attachment technology called NRS™.

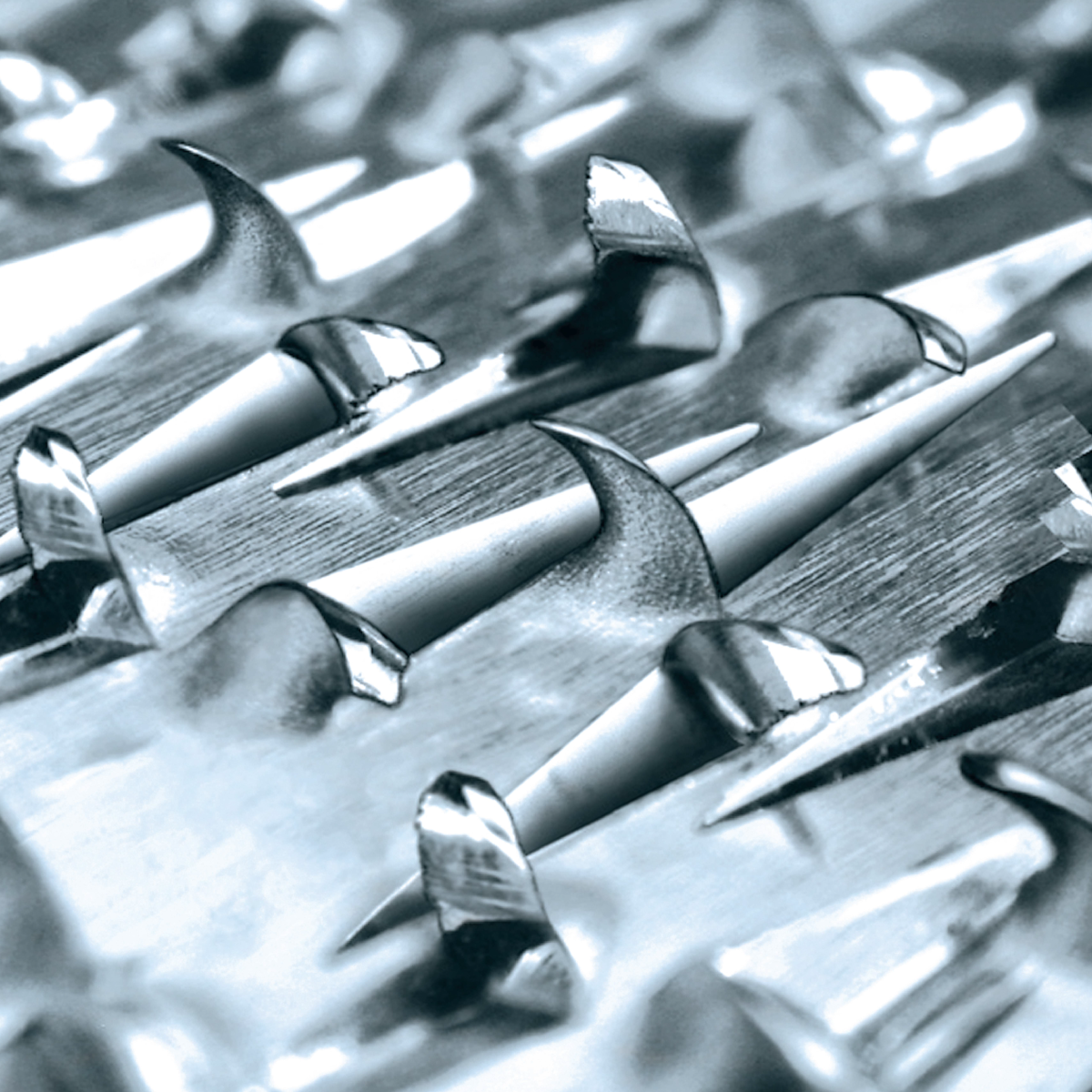

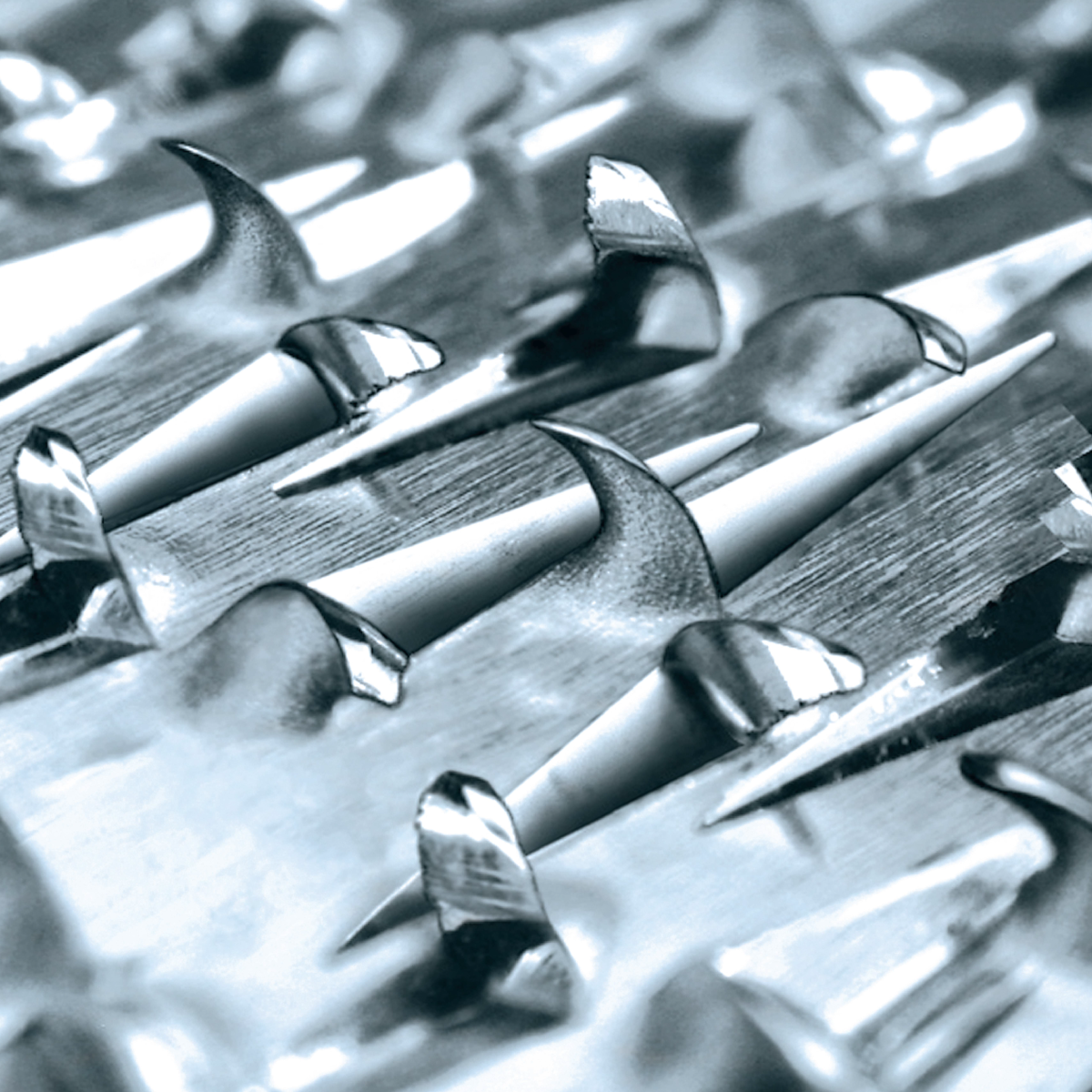

Patented NRS Technology

We have engineered a Safety Braking Zone into every one of our brake pads. Instead of adhesives, our brake pads use NRS hooks to secure the friction to the galvanized backing plate. These hooks provide a mechanical retention of the friction material, overcoming inadequacies of adhesive usage. This guarantees that the friction material will never delaminate, providing a longer life and safer brake operation for the entire life of the pad.

Fully Galvanized Backing Plate

A majority of after-market brake pads today use painted back-plates and inconsistently applied adhesives to bond the friction material to the back-plate. These adhesives are easily thermally degraded during normal service. NRS galvanic protection prevents corrosion and its ingress, affording a very robust rust inhibition over the life-time of the brake pad. Brake pads ought not to be replaced for back-plate corrosion well before they actually wear out!

Premium Friction Materials

We use the best engineered friction materials in our brake pads. Our semi-metallic brake pads have more durability and longevity than traditional pads. Ideal for passenger cars, light trucks, vans, import and domestic, our brake pads stop sooner, last longer, and are significantly quieter than traditional brake pads.

Patented NRS Technology

We have engineered a Safety Braking Zone into every one of our brake pads. Instead of adhesives, our brake pads use NRS hooks to secure the friction to the galvanized backing plate. These hooks provide a mechanical retention of the friction material, overcoming inadequacies of adhesive usage. This guarantees that the friction material will never delaminate, providing a longer life and safer brake operation for the entire life of the pad.

Fully Galvanized Backing Plate

A majority of after-market brake pads today use painted back-plates and inconsistently applied adhesives to bond the friction material to the back-plate. These adhesives are easily thermally degraded during normal service. NRS galvanic protection prevents corrosion and its ingress, affording a very robust rust inhibition over the life-time of the brake pad. Brake pads ought not to be replaced for back-plate corrosion well before they actually wear out!

Premium Friction Materials

We use the best engineered friction materials in our brake pads. Our semi-metallic brake pads have more durability and longevity than traditional pads. Ideal for passenger cars, light trucks, vans, import and domestic, our brake pads stop sooner, last longer, and are significantly quieter than traditional brake pads.

Forget buying traditional brake pads again.

Instead of adhesives, our brake pads have In-situ galvanized hooks - called NRS™ on the backing-plate surface. These hooks provide a mechanical retention of the friction material, overcoming inadequacies of adhesive usage.

This guarantees that the friction material will never delaminate, providing a longer life and safer brake operation for the entire life of the pad.

Understand The NRS Galvanized Difference

-

Galvanized Steel Construction

NRS Brake Pads will never delaminate. All NRS steel backing plates are galvanized to ensure friction works to the last millimetre.

Galvanized Steel Construction

NRS Brake Pads will never delaminate. All NRS steel backing plates are galvanized to ensure friction works to the last millimetre. -

OEM Fit Tolerances

Fits right out of the box. NRS Brakes exceed OEM standards, delivering superior performance and durability for every vehicle.

OEM Fit Tolerances

Fits right out of the box. NRS Brakes exceed OEM standards, delivering superior performance and durability for every vehicle. -

Award Winning Technology

Instead of adhesives, our brake pads use NRS hooks to secure the friction to the galvanized backing plate. These hooks provide a mechanical retention of the friction material, overcoming inadequacies of adhesive usage.

Award Winning Technology

Instead of adhesives, our brake pads use NRS hooks to secure the friction to the galvanized backing plate. These hooks provide a mechanical retention of the friction material, overcoming inadequacies of adhesive usage.