Researched & Developed

We Don't Gamble With Brake Safety.

By putting our brakes though every imaginable wear test, we can guarantee they last and brake safely, down to the last milimeter.

Corrosion Spray Testing

We simulate years of corrosive brake wear over a few hours while testing each of our brake pads.

Extreme Wear Tested

Our competitor's pads are put through the same rigourous process and they always fail. NRS guarantees safe, operational brake pads even to the last milimeter of friction.

Noise Testing

We put our brakes through SAE standard J2521 noise test. This test consists of 1400+ stops at various pressures, velocities, and temperatures. NRS Brakes prevent what are considered noisy stops - a frequency greater than 70dB noise rating.

Over 20,000+ Tested Brakes

We gather every competitor, OE and aftermarket available and put them through the same strenuous testing. Understanding their failure points ensure our brake pads to exceed all expectations.

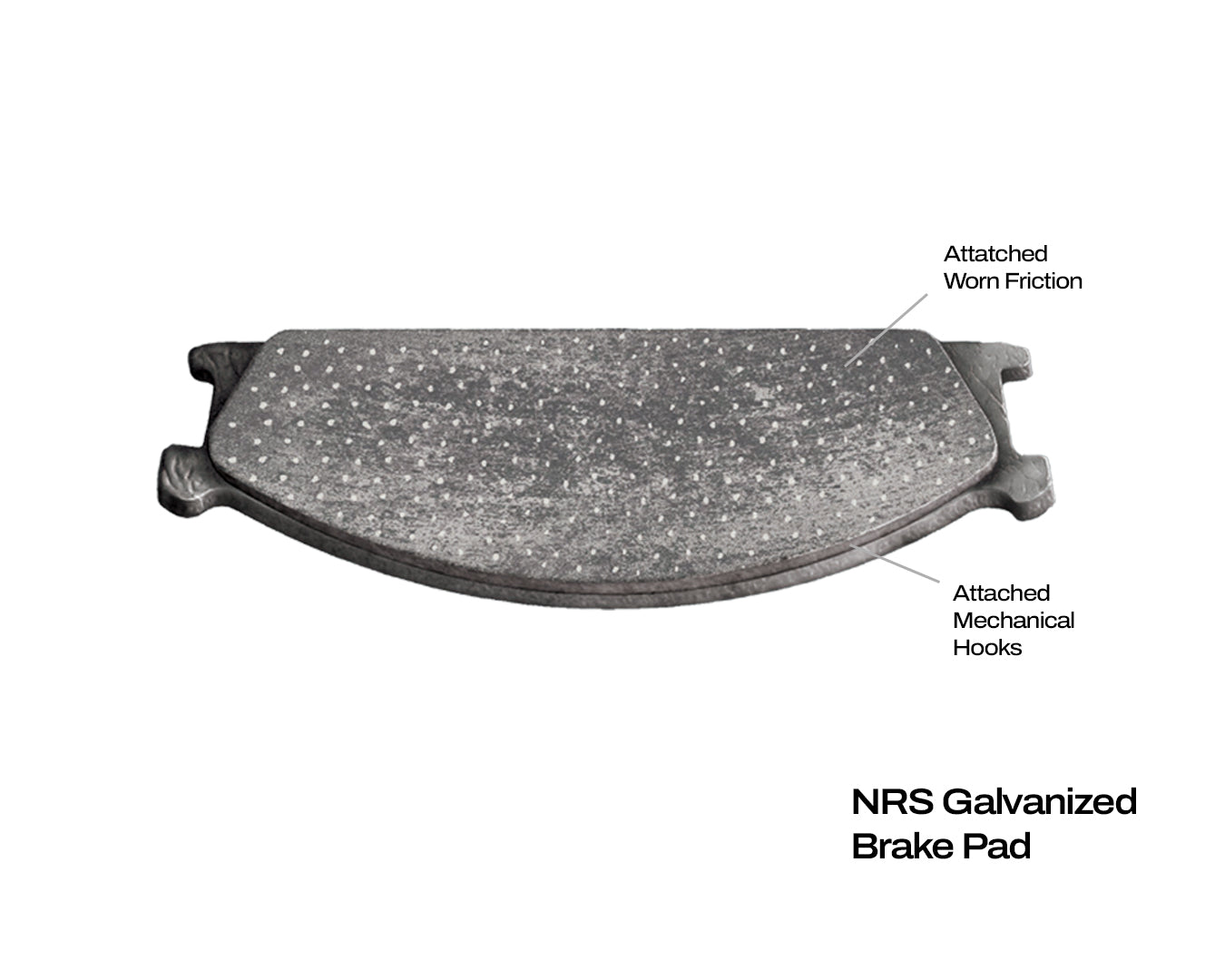

NRS Galvanized Brakes VS. Painted Pads

Never worry about early brake failure or delamination issues again. NRS Galavnized Brake Pads have been developed to ensure safe braking to the last millimeter of friction.