Galvanized Brake Pads Specifically Engineered for Hybrid and Electric Vehicles

Engineered to meet the specific braking needs of hybrid and electric vehicles for optimal performance.

Why Pads Deteriorate Due to Regen Braking:

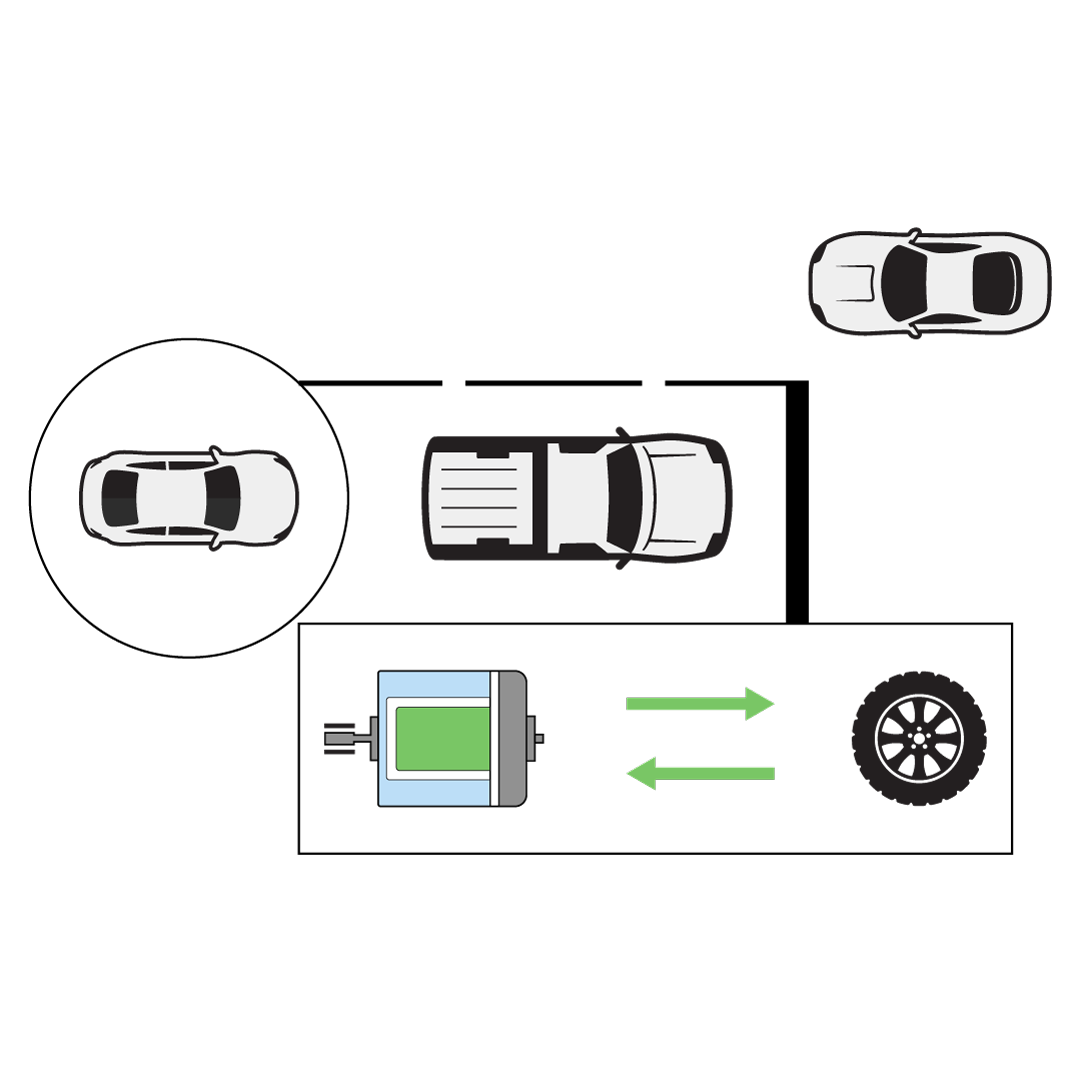

Hybrid and electric cars brake differently than gasoline powered vehicles. A gasoline vehicle uses brakes frequently, causing them to heat and dissipate moisture.

Hybrid and electric cars use their electric motor

to slow the vehicle, resulting in less frequent use of your brakes

This can cause moisture buildup, corrosion, and premature brake failure.

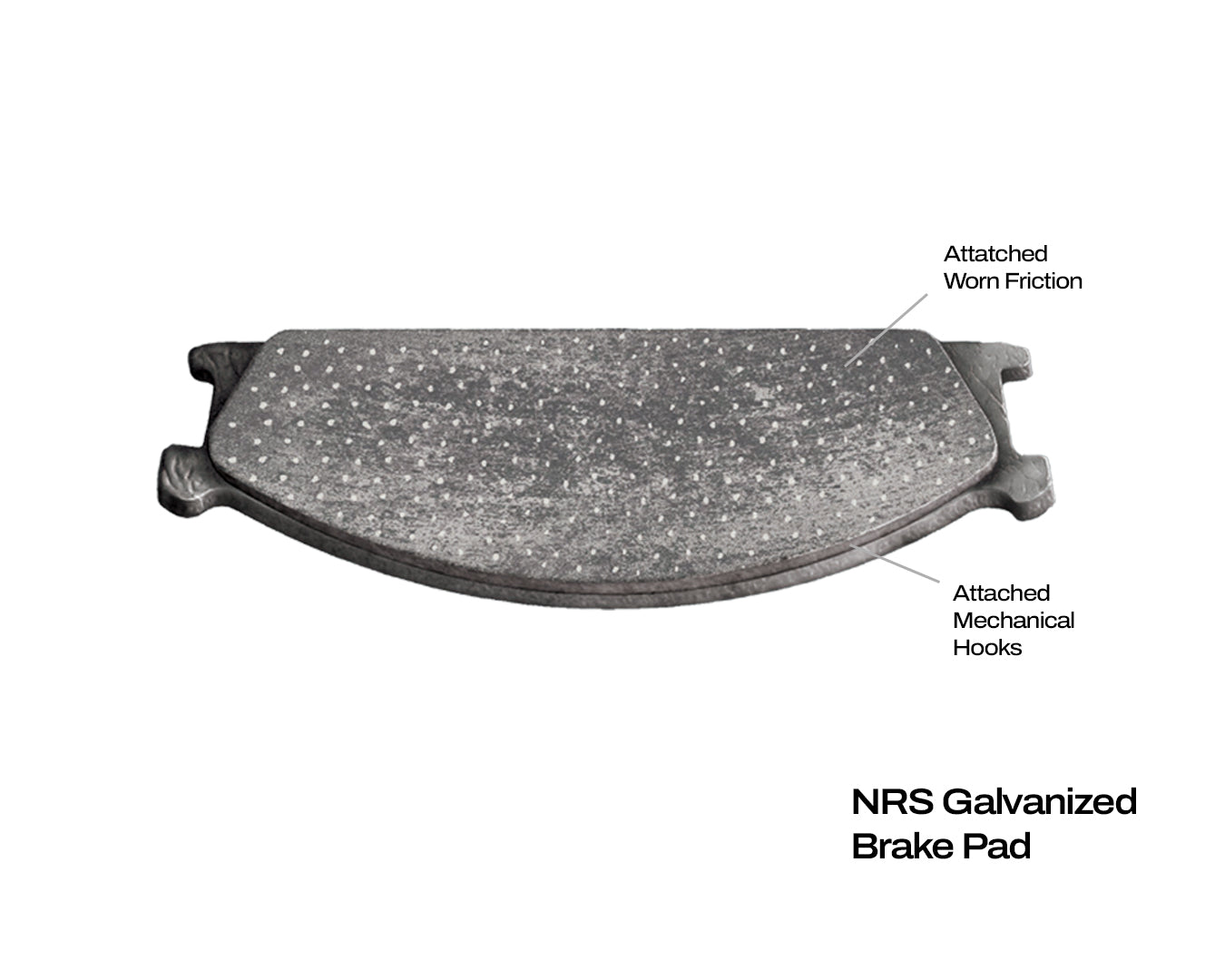

The Next Generation Brake Pad

The electric vehicle market is exploding and aftermarket manufacturers – and even some OEMs – are pushing outdated brake pads that weren’t designed for your EV. While EV brake replacement can be expensive, don’t be tempted by cheap aftermarket parts or pricey dealer replacements that don’t do the job.

Only zinc plated NRS-EV brakes are specifically engineered for your EV. NRS Brakes conclusive research provides the proof. Make the right choice for your EV.

No Paint

Free from harmful paints, ensuring a cleaner, eco-friendly product.

No Copper

Copper-free design, reducing environmental impact and meeting strict regulations.

No Lead

Lead-free construction for safer, non-toxic brake pads.

No Paint

Free from harmful paints, ensuring a cleaner, eco-friendly product.

No Copper

Copper-free design, reducing environmental impact and meeting strict regulations.

No Lead

Lead-free construction for safer, non-toxic brake pads.

Your EV is Eco-Friendly, Why Not Your Brake Pads?

Maybe it’s the changing times or NRS Brakes heightened awareness of climate change that makes us all care more about what goes into the products we buy. NRS Brakes has always crafted premium brake pads to meet the highest possible standards for environmental safety and sustainability.

NRS Brakes Ultra-Premium products are environmentally friendly and adhere to the new low copper requirements under California and Washington restrictions.

NRS metallics and copper-free ceramics

already meet the LEVEL A, B, and N mandated U.S. regulations.

These symbols are your assurance that NRS Brakes is committed to our environment. NRS brake pads are 100% copper-free and are 100% recyclable.

The LeafMark™ is a trademark of The Motor and Equipment Manufacturers Association.

NRS Brakes unmatched commitment to the environment means that you can always expect NRS to deliver the longest lasting, safest and most environmentally friendly brake pad for electric, hybrid and autonomous vehicles.

Where Does All That Debris Go?

Brake pad debris, including harmful toxins like copper, lead, and rust, can pollute our air, water, and soil, impacting the environment and public health.

Upgrade Your Brakes Today

Don't rely on traditional brake pads for your EV. Go Galvanized.