The Galvanized Difference

Our Patented Galvanization process was accomplished through testing 10,000+ OE and aftermarket brake pads over the last decade.

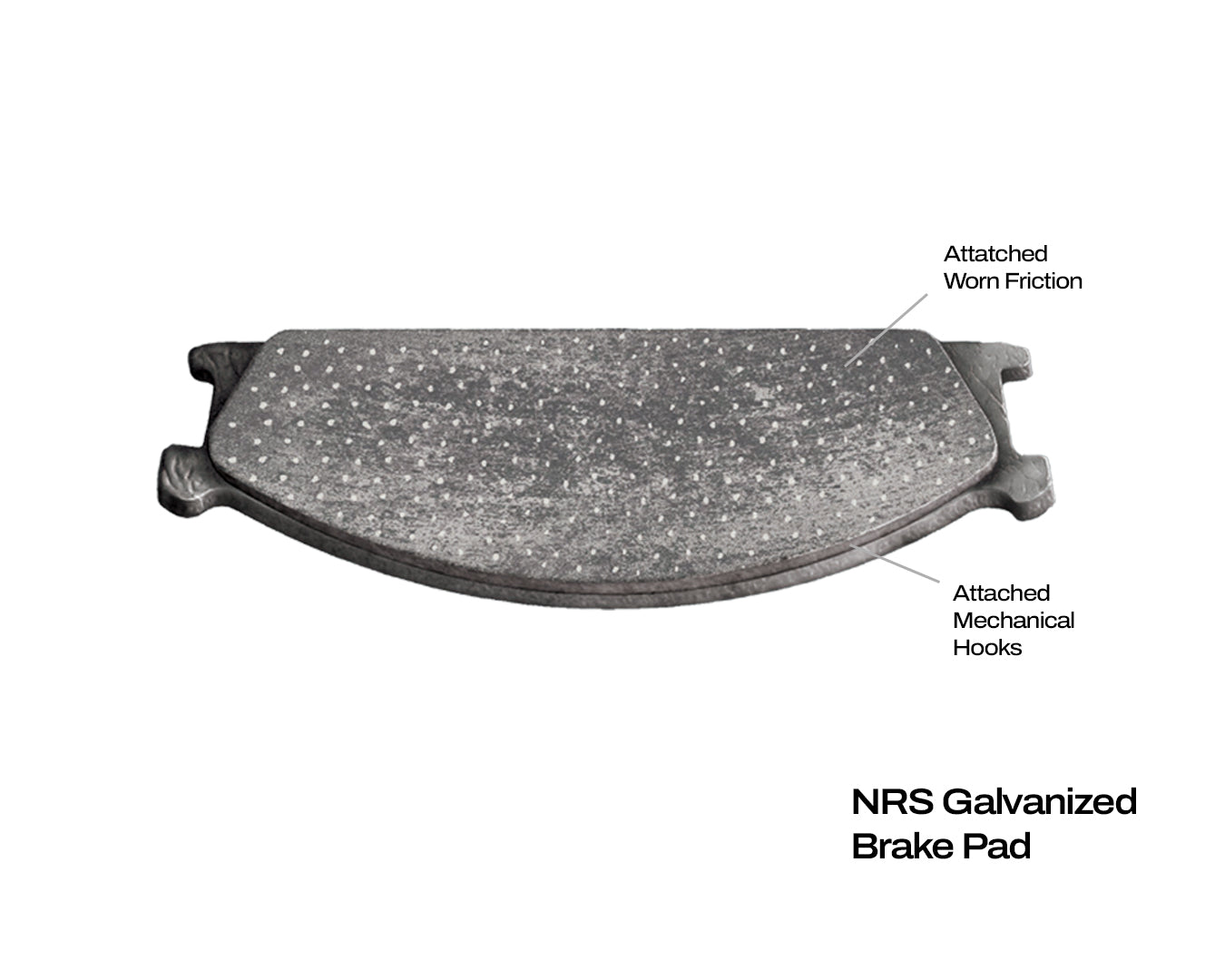

Patented NRS Technology

We have engineered a Safety Braking Zone into every one of our brake pads. Instead of adhesives, our brake pads use NRS hooks to secure the friction to the galvanized backing plate. These hooks provide a mechanical retention of the friction material, overcoming inadequacies of adhesive usage. This guarantees that the friction material will never delaminate, providing a longer life and safer brake operation for the entire life of the pad.

Premium Friction Materials

We use the best engineered friction materials in our brake pads. Our semi-metallic brake pads have more durability and longevity than traditional pads. Ideal for passenger cars, light trucks, vans, import and domestic, our brake pads stop sooner, last longer, and are significantly quieter than traditional brake pads.

Fully Galvanized Backing Plates

A majority of after-market brake pads today use painted back-plates and inconsistently applied adhesives to bond the friction material to the back-plate. These adhesives are easily thermally degraded during normal service. NRS galvanic protection prevents corrosion and its ingress, affording a very robust rust inhibition over the life-time of the brake pad. Brake pads ought not to be replaced for back-plate corrosion well before they actually wear out!

Patented NRS Technology

We have engineered a Safety Braking Zone into every one of our brake pads. Instead of adhesives, our brake pads use NRS hooks to secure the friction to the galvanized backing plate. These hooks provide a mechanical retention of the friction material, overcoming inadequacies of adhesive usage. This guarantees that the friction material will never delaminate, providing a longer life and safer brake operation for the entire life of the pad.

Premium Friction Materials

We use the best engineered friction materials in our brake pads. Our semi-metallic brake pads have more durability and longevity than traditional pads. Ideal for passenger cars, light trucks, vans, import and domestic, our brake pads stop sooner, last longer, and are significantly quieter than traditional brake pads.

Fully Galvanized Backing Plates

A majority of after-market brake pads today use painted back-plates and inconsistently applied adhesives to bond the friction material to the back-plate. These adhesives are easily thermally degraded during normal service. NRS galvanic protection prevents corrosion and its ingress, affording a very robust rust inhibition over the life-time of the brake pad. Brake pads ought not to be replaced for back-plate corrosion well before they actually wear out!

Avoid Unnecessary Brake Jobs

NRS brake pads are the world’s longest lasting brake pads for a reason. We use galvanized steel construction and premium friction materials, making sure you have the same stopping power throughout the life of the entire brake pad.

NRS also uses patented NRS™ technology ensuring the friction material never delaminates from the backing plate, giving you more secure, safer stops.

Corrosion Resistant

Built To Last

Environmentally Friendly

A Match For Harsh Environments

Less Vibration, Less Noise

Optimal Performance

Corrosion Test

We our our brake pads through extreme corrosion testing to compare the benefits of our galvanized process against aftermarket pads.

12 Month Review by Chris Fix

The Next Generation Brake Pad is Galvanized

Covering All Vehicle Types

Electric Vehicles (EV)

Regnerative braking? No problem.

Fleet Vehicles

Built for heavy duty.

Consumer Vehicles

Brakes for every daily.

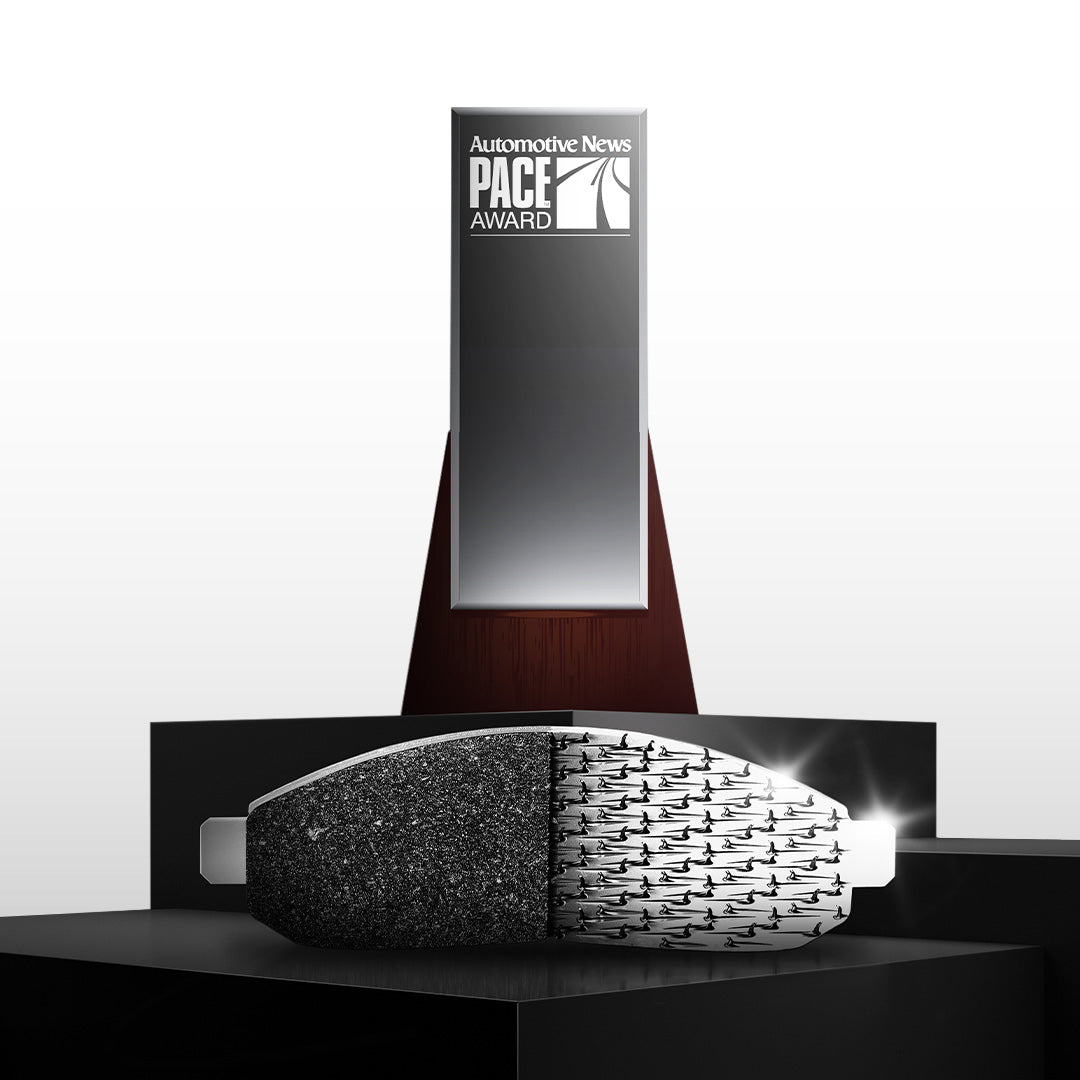

PACE Award Winning Innovation

The game changing award-winning NRS technology was awarded the PACE award where the judges cited “NRS is a compelling example of an innovative solution to an unsatisfactory but accepted process in the automotive industry" - PACE Award Judges