Why Galvanized?

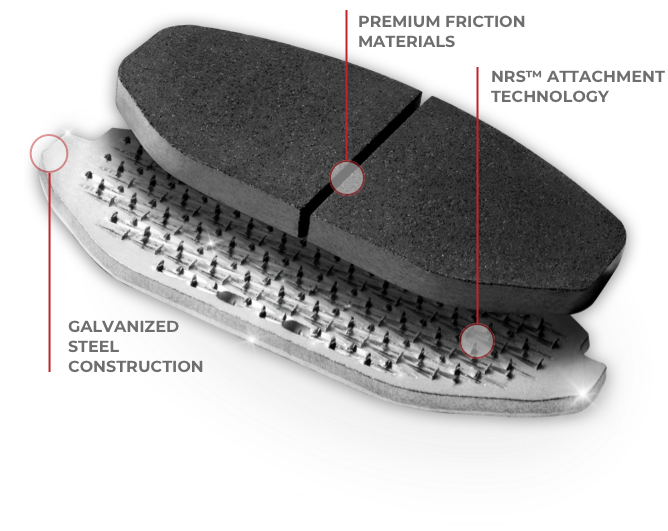

Right out of the box, galvanized NRS Brakes have a technology you can see. Rust resistant, unpainted galvanized steel with zinc plating incorporates an award-winning attachment technology called NRSTM

Right out of the box, galvanized NRS Brakes have a technology you can see. Rust resistant, unpainted galvanized steel with zinc plating incorporates an award-winning attachment technology called NRSTM

Advantages of Galvanized Pads vs.Traditional Pads

NRS brake pads are the world’s longest lasting brake pads for a reason. We use galvanized steel construction and premium friction materials, making sure you have the same stopping power throughout the life of the entire brake pad.

NRS also uses patented NRS™ technology ensuring the friction material never delaminates from the backing plate, giving you more secure, safer stops.