Why NRS?

NRS solid plates demonstrate a 40% improvement in resistance to deflection under load. While this is immediately important in minimizing friction “cracking” and degradation, it also minimizes damage to the caliper abutment and rotor.

Tested beyond the breaking point

NRS has earned the reputation of being “bulletproof in its resistance to shear loads, deflection and heat. NRS-applied pads allow friction manufacturers to engineer friction products that demonstrate an extended duty cycle by retaining overall plate/pad integrity to the absolute end of friction wear.

SHARKMetal™

The patented mechanical attachment system

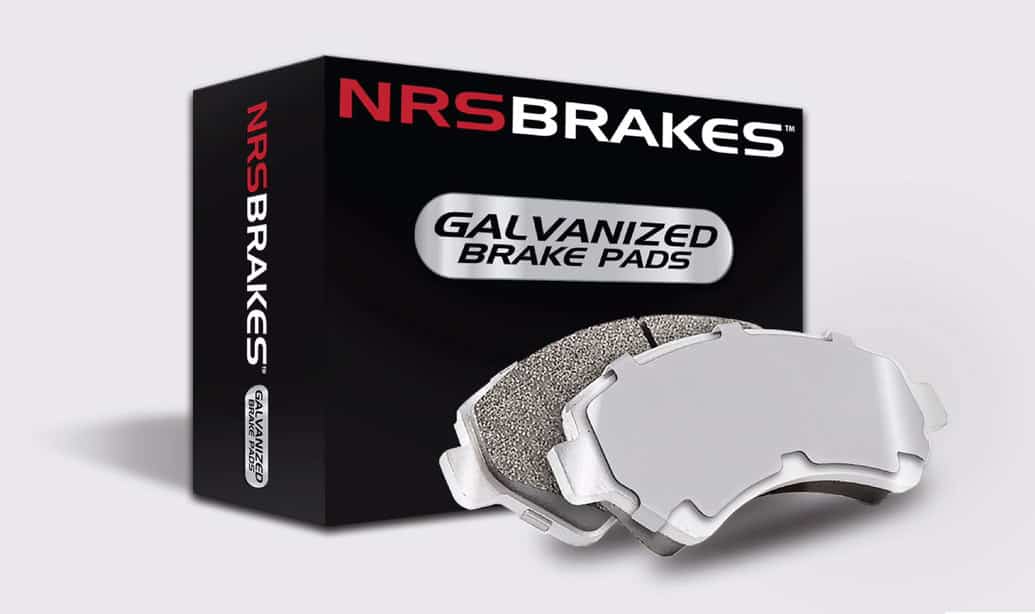

Instead of adhesives, our brake pads have In-situ galvanized hooks

- called SHARKMetal™ on the backing-plate surface. These hooks provide

a mechanical retention of the friction material, overcoming inadequacies

of adhesive usage, dramatically improving shear strength and life-cycle of brake pads.

This guarantees that the friction material will never delaminate, providing

a longer life and safer brake operation for the entire life of the pad.